Personalized material solutions

Assisting in all aspects of material selection and production of your solar cell connector requirements, Ulbrich’s team of expert metallurgists personalize material solutions to suit your precise needs and manufacturing processes.

Rapid prototype to production

Ninety years of history in working with metals, and a proven testing process, has lead our process metallurgists to the forefront in prototyping. You’ll be assisted by the same in-house metallurgist each time, enabling you to establish a strong working relationship.

State-of-the-art equipment

Ulbrich’s expert metallurgists have access to some of the most exclusive advanced equipment in the world. But, it’s the unrivaled know-how and personalized connection to the metallurgists using the best equipment that makes all the difference.

POWER ENHANCING & SPECIAL PRODUCTS

MTW

Multi-Tabbing Wire is the newest development for the multiple Bus-bar technology. Over the years, UST has leveraged experiences in product development, manufacturing and marketing competences to engineer a solder coated copper round wire for cell interconnection.

Ulbrich’s Multi-Tabbing Wire offers the same high quality and product performance standards you are familiar with from all our other products we supply to the PV Industry. Multi-Tabbing Wire is available in all common copper grades including high-purity oxygen-free copper. There are no limitations regarding the available dimension you need to build the best performance modules. We have developed a solder coating process to achieve concentric coating layers to guarantee consistent soldering results in the stringing process. The options of solder materials have been expanded to include bismuth and indium alloys, in addition to our standard SnPb alloys.

POWER ENHANCING & SPECIAL PRODUCTS

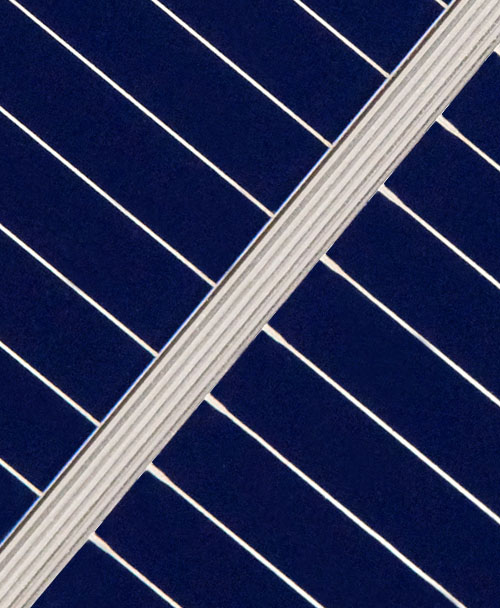

LCR

LCR™ is a high efficiency grooved solar cell interconnect wire that replaces traditional flat ribbon used to connect solar cells together within a module. It was developed to increase the efficiency of a solar module by reflecting more light back onto the surface of the cell. This innovative grooved interconnect wire steers the reflected light back to the glass/air interface allowing total internal reflection back onto the cell surface. Up to 80% of the incoming light that strikes the LCR™ ribbon is recovered significantly higher than the 5% recovery of traditional solar cell tabbing and interconnect wire.

POWER ENHANCING & SPECIAL PRODUCTS

rrr

Sed a dui at sapien porttitor placer pendssee rutrumorem efficitur nibh condimentum aci Nam lorem libero, imperd imat, fermentumy vehicula nulla. Aenean gravida leo non lorem egesta tristque extin. Morbi at libero eleifend matie vitae, lacnelis.

Sed a dui at sapien porttitor placer pendssee rutrumorem efficitur nibh condimentum aci Nam lorem libero, imperd imat, fermentumy vehicula nulla. Aenean gravida leo non lorem egesta.