About Ulbrich Solar Technologies

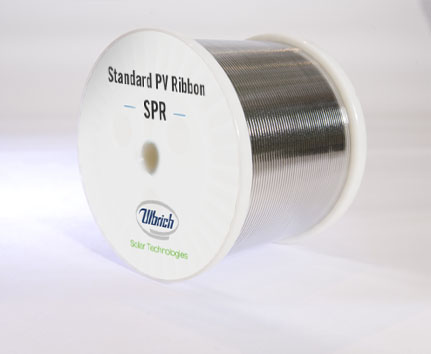

Ulbrich continues to be a world leader in PV Ribbon products that interconnect and transmit current for crystalline solar cells and thin film. For decades, we have supplied the Solar Industry with our tinned flat copper wire, continually identifying emerging PV Ribbon technologies and engineering innovative solutions to increase the electrical output and performance of solar modules.

R&D and Quality Focus

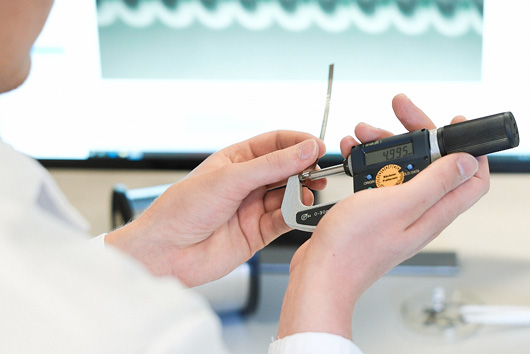

Our Research Team and Applications Engineers develop customized products and processes that supply cost-effective solutions to module manufacturers around the globe.

The continuous success of our leading products is based on the highest quality in the solar market. The world’s best solar module manufacturers have been using Ulbrich’s PV Ribbon for decades as the consistent Quality always helped them to improve their own products and reduce the total cost.

Contact a specialist

Whether we’re planning, engineering, or manufacturing our precision-made metals, we’re ready to provide the guidance your vision needs. Let’s chat.